Revolutions

Industry 4.0 digitalization including ubiquitous data capacity (in the cloud), data science (analytics), Machine Learning

(supervised and unsupervised) and Deep Learning is the current industrial revolution. If I am leading a team at an

organization where I have a lot of data across accounting, operations, sales and other views what does this mean in terms

of practical approaches and tools?

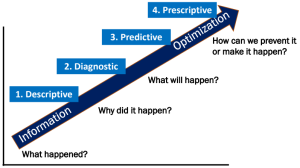

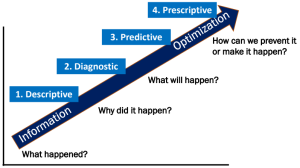

Industry 4.0 is a journey to an optimization system for making better business decisions with

multiple increasingly successful stages and milestones along the way.

What is it?

Essentially, it is to pull predictions on the operations of an organization by applying tools to the data produced in the day-

to-day business activities of that same organization allowing for prescriptive actions that will result in a specific outcome.

-

Descriptive: The first layer of data collection and analysis is the descriptive. It tells you What happened? Simple

reporting. Trying to control a process based on this level of data and analytics is bit like driving by looking in the rear

view mirror. We have collected data.

- Diagnostic: The second layer of data collection and analysis is determining “Why it happened?” Root Cause Analysis

is an example. The data is analysed across multiple views to determine why. It informs and perhaps provided future

corrective action. But little to help when it happened. We have collected and analysed data to provide information.

- Predictive: The third layer of data collection and analysis is determining ‘What will happen?” From the data provided

a future event is specified. It is the beginning of the control feedback loop. Information has resulted in a forecast.

- Prescriptive: The fourth layer of data collection and analysis is the point of Industry 4.0. “How can we prevent or

make it happen?” Forecast has become a call to action.

The higher the quality of data (correlation to business outcome) the better the business

process machinery and actions.

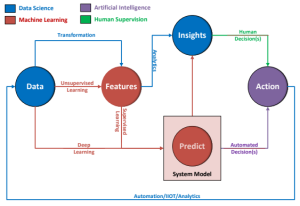

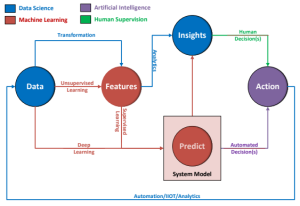

- The first order of business is data. From the various sources of data (ERP, Accounting, Operations, SCADA,

Automation) to where the final data for purposes of Industry 4.0 will reside (cloud, on-premises).

- Features are determined from the data by analysis and Transformation or perhaps one of many powerful

Unsupervised Learning band publicly available Algorithms to find patterns in the data and provide features.

- Insights can come directly from applying data science Analytics to the transformed data or supplied by an Artificially

intelligent System Model to Predict outcomes

- Action(s), result either by Human Decisions based on the Insights or can be Automatically Prescribed from the

Predictive System Model.

- Automation/IIOT/ Analysis provides a feed back into the data that is used by the system continuously improving it.

It is a journey that can involve several steps, from the simplistic to the complex depending on the solution selected.

It is a journey that can involve several steps, from the simplistic to the complex depending on the solution selected.

- Assignment of system design, analysis, data collection and other activities to Industry 4.0 skilled individuals.

- Big Data considerations on collection and storage of data collected.

- The problem targeted.

- Proof of Concept development and review.

- Analysis of differing methods from Data Science treatment of data to Machine Learning to select an approach.

- Feature Engineering and Data Analysis

- Security (Cyber and physical)

- Final Implementation form factor/design

- Post Implementation Operations

- Testing

- Validation

Industry 4.0 and the tools it relies on, is a journey to attain business value and optimization of

organizations through their data and incremental continuous improvement.